A1 Alfatechnic Sandblasting Pots

Sandblasting Pots

Alfatech has a wide range of blasting machines as either manual or automatic from 25 lt to 8000 lt. Each blast pot is manufactured to be fit for your purpose.

Sandblasting pots are used for abrasive blasting of metal constructions and buildings, bridges, reservoirs, piping, and concrete surfaces, shipbuilding industry, storage and transport tank, historical artifacts, all steel industries.

Automatic Sandblasting Pots

The most important information that should be emphasized in our Alfatechnic Automatic Sandblasting boilers With two (2) personnel for 1 beach boilers instead of two (2) personals of our manual sandblasting boilers, things progress more safely, effectively and quickly. With the latch used in our automatic sandblasting boilers, it can both make application and make it in a shorter time and noiseless for opening and closing. The automatic stop causes the machine to stop itself. This eliminates the feared work accident.

| A1 ALFATECHNIC AUTOMATIC SANDBLASTING POTS | ||||||

| Matching Table | ||||||

| Features | AT-25RC | AT-50RC | AT-100RC | AT-200RC | AT-300RC | Specifications |

| Capacity | 25 lt | 50 lt | 100 lt | 200 lt | 300 lt | Capacity |

| Maks. Working pressure | 10 bar | 10 bar | 12 bar | 12 bar | 12 bar | Max. Work.Pressure |

| Height | 750mm | 1100mm | 1120mm | 1500mm | 1800mm | Height |

| Diameter | 300mm | 350mm | 650mm | 650mm | 650mm | Diameter |

| Weight | 40 kg | 60 kg | 100 kg | 130 kg | 190 kg | Weight |

| K.Exit | 1/2″ | 1″ | 1″ | 1 1/4″ | 1 1/4″ | P. Output |

Blasting pots with valve sytems,resistant to steel grit applications and suitable for automatic loading system. Please contact for further details.

Manual Sandblasting Pots

As it is known, our Alfatechnic Manual Sandblasting boilers are suitable for operating with two personnel. While one personnel is applying, the other personnel should wait at the beginning for the safety of the blasting boiler and make the blasting boiler open and close. It is a preferred boiler in places where sandblasting works are low.The subsystem of our Alfatechnic Sandblasting Boilers is Contracor SGV steel grit valve, as shown in the picture. Wear time takes much longer if this valve is used. Just replace the gasket inside the val

| A1 ALFATECHNIC MANUAL SANDBLASTING POTS | |||||||||

| Matching Table | |||||||||

| Features | AT-25 | AT-50 | AT-100 | AT-200 | AT-300 | AT-500 | AT-1000 | AT-8000 | Specifications |

| Capacity | 25 lt | 50 lt | 100 lt | 200 lt | 300 lt | 500 lt | 1000 lt | 8000 lt | Capacity |

| Maks. Working pressure | 6 bar | 6 bar | 8 bar | 8 bar | 8 bar | 8 bar | 8 bar | 8 bar | Max. Work.Pressure |

| Height | 750mm | 1100mm | 1120mm | 1500mm | 1800mm | 1700mm | 2000mm | 5500mm | Height |

| Diameter | 300mm | 350mm | 650mm | 650mm | 650mm | 720mm | 900mm | 1600mm | Diameter |

| Weight | 40 kg | 60 kg | 100 kg | 130 kg | 190 kg | 250 kg | 450 kg | 1900 kg | Weight |

| K.exit | 1/2″ | 1″ | 1 “ | 1 1/4″ | 1 1/4″ | 1 1/4”x1 | 1 1/4″x2 | 1 1/4″x2 | P. Output |

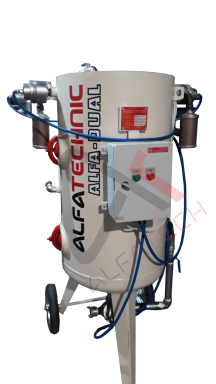

ALFA Dual Chamber Blast Machine (ALFA DUAL)

You can use our ALFA double chamber blast machines for your continuous work Up to four operators at the same time. ALFA double chamber systems allow you to refill the blast machine and continue your process without interrupting your blasting process. ALFA double chamber system is a perfect solution for an automated production and continuous work.

Innovations

The CAF filter eliminates up to 98% of the condensate and oil from compressed air. This prevents work stoppages in connection with the removal of dampened abrasive from the tank.

DBS serisi 100 litre ve 200 litre tank kapasiteli kumlama kazanları ekipmanları:

Equipments

1- Cover

2- Screen

3- Machine tank

4- Pressurizing ball valve

5- Upper air line ball valve

6- Moisture and oil seperator CAF-1

7- Lower air line ball valve

8- Abrasive blasting hose UNIFLEX

9- COMFORT Operator helmet

10- Nozzle holder

11- Nozzle

12- Breathing air hose

13- Breathing air filter BAF-1

| CONTRACOR DBS SERIES SANDBLASTING POTS | |||

| Matching Table | |||

| Specifications | DBS-100 | DBS-200 | |

| Capacity | 100Lt | 3-4m² | |

| Max. Work Pressure | 10 Bar | 7 Bar | |

| Height | 1226mm | 25Lt | |

| Diameter | 508mm | Dahili/Internal | |

| Weight | 105kg | 118 Kg | |

| Working Temperature | 10ºC/50ºC | 10ºC/50ºC | |